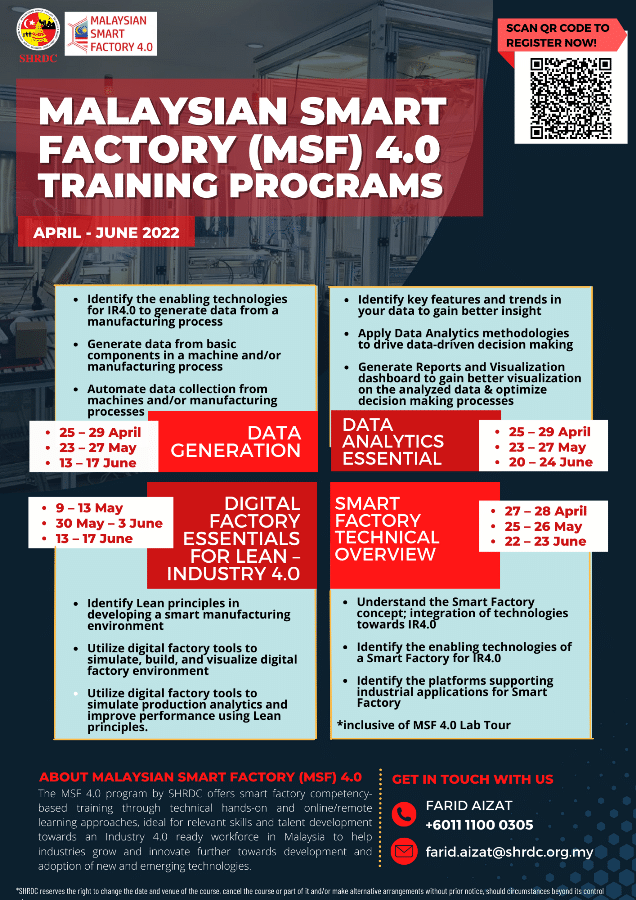

21 Apr MALAYSIAN SMART FACTORY (MSF) 4.0 TRAINING PROGRAMS

APRIL – JUNE 2022 SCHEDULE

Hurry up and register with us Now!

You wouldn’t want to miss out on our hot selling Q2 MSF 4.0 training programs

REGISTER HERE https://forms.office.com/r/iQtAtB4Xj3

Sorry, the comment form is closed at this time.